FreeMove Productivity: Machine Tending Case Study Part 1

By Pritha Vijay, Director, Product, Veo Robotics

In past case studies, we examined how the Veo FreeMove system enables improved economics in dual fixture assembly and palletizing. Today we will consider another application in detail: machine tending, a common human-robot collaborative application. A basic form of machine tending is where human workers move parts or materials into a workcell and a robot then picks up and processes the parts or loads them into another machine (the “machine” being “tended”) such as a press, laser cutter, or CNC tool. The robot then places the finished product in an output bin for the human worker to remove from the workcell.

The Setup:

A parts manufacturer was looking to improve the productivity of a machine tending workcell through better human-robot collaboration. The workcell was designed for an industrial robot to move the front panels of a circuit breaker to and from a laser cutting machine, a typical metal fabrication operation. In this process flow, a human brought in a pallet rack of unprocessed parts to be laser cut, then the robot picked up a part from the pallet rack, inspected it, and if it passed QC, loaded it into the laser cutter. Defective parts were dropped on a separate pallet. When the laser cutting was finished, the robot unloaded the part and placed it on an output pallet for the human worker to withdraw when full.

Figure 1. Original workcell architecture.

As shown in Figure 1, the robot had access to five pallet racks for unloading materials and loading parts: the two on the left for raw materials, the two on the right for the finished parts, and the center pallet rack for defective parts. When any of the pallets became full or empty, a human operator replaced them.

Ensuring that these kinds of collaborative robotic workcells are safe for human entry requires the integration of safety systems in addition to the robot, fixturing, and programming for the application itself. In this case, to allow operators to safely enter and exit, the workcell was safeguarded by three 2D area scanners guarding planes perpendicular to the fences, and one light curtain set at the entrance of the workcell, serving as a virtual fence.

Designing and implementing a workcell with these disparate safeguarding elements is time-consuming, requiring extensive ladder logic development, testing of possible breach sequences, calculations of protective separation distances, and risk assessments. The design and implementation are also inflexible, and as we discussed in our last case study, the flexibility to quickly and easily reconfigure a workcell is immensely valuable.

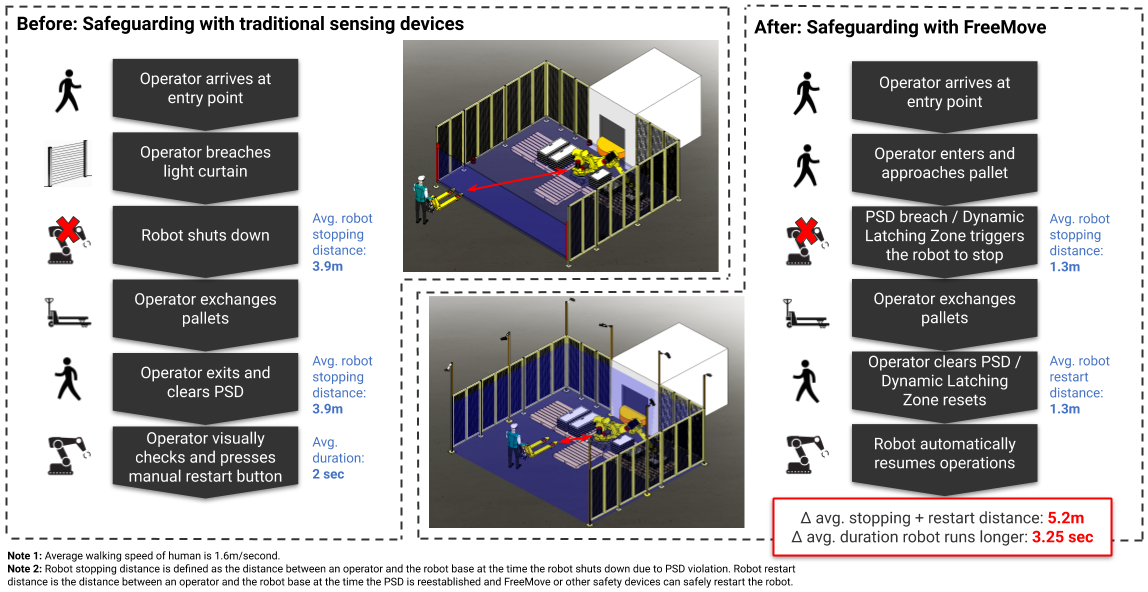

To exchange a pallet or perform maintenance inside the workcell, an operator would have to breach the light curtain, triggering the robot to stop the moment the operator entered the workcell (Figure 2). The robot could only restart once the operator had completed their task, fully vacated the workcell (re-establishing the static Protective Separation Distance), and pressed a button to resume operations.

The Protective Separation Distance (PSD), according to manufacturing safety standards, is the minimum distance between a human and a robot at which the robot is required to stop to ensure the safety of the human. Traditional sensing devices (like light curtains and area scanners) use static PSDs that are set based on the worst-case scenario (in this case, when the robot arm is fully extended toward the front of the workcell and a human is approaching it directly).

Additionally, workcells guarded by traditional sensing devices are typically designed to require manual restarting to avoid additional complicated application design, engineering, and risk assessment—all of which contribute to a lengthy process and higher set-up costs.

Figure 2. Sensors trigger robot shutdown when static PSD is violated.

If we assume that an operator must enter the workcell 32 times per shift on average, with three shifts a day, that comes to 96 human entry events a day. With traditional sensors and a static PSD, each human entry event would cause the robot to stop for the time it takes the operator to move between the entry point of the workcell and the location of the task, plus the time it takes to complete the task, plus the time it takes to exit the workcell, plus the time it takes the operator to visually check for a safe state and press the manual restart button (check out one of our other blog posts for more on inefficiencies caused by downtime).

To increase productivity, the manufacturer sought a solution that would allow the robot to run while the operator entered the workcell to replace pallets—i.e., a solution that would safely reduce PSD so humans could be closer to the robot while it was still operating.

Enter Veo

In order to reduce downtime, improve productivity, and boost revenue, the manufacturer decided to work with Veo Robotics to design a workcell using FreeMove. Unlike traditional sensing devices, FreeMove is a single comprehensive system that monitors a complete volumetric safeguarded space, enabling dynamic PSD monitoring.

Figure 3. New workcell architecture with Veo FreeMove.

A dynamic PSD is calculated based on the actual positions of the robot and human, derived from the 3D state of the workcell as observed by FreeMove Sensors mounted on its periphery (Figure 3). FreeMove’s real-time understanding of the space enables dynamic computation of the extent of the robot hazard, which changes with the position and speed of the robot and workpiece. The FreeMove Engine uses the 3D data to identify where the robot, workpiece, humans, and any occlusions are in the workcell. It then calculates all possible future states of the workcell and signals the robot to stop if a human might violate the PSD.

When FreeMove determines that it is safe for the robot to move again, it signals the robot to restart automatically. FreeMove supports safe and reliable automatic restart because it monitors the workcell in 3D and can predict safe and unsafe states in real time. Consequently, the robot can continue operating until a human violates the dynamic PSD or the human touches a muted zone (Figure 4).

Muted zones are volumes of the workcell that are deliberately left out by FreeMove during dynamic PSD calculations so that the system does not confuse them for humans and stop the robot. Confusion may occur, for example, if the muted volume is in motion (like a conveyor) or changing in volume over time (like a pallet being assembled).

In this application, the pallet racks are muted zones because they are constantly changing shape as material is picked up and deposited by the robot. In the absence of muting, the pallets would be classified by the system as unrecognized objects, and if their distance to the robot is less than the allowed PSD, FreeMove will signal the robot to stop unnecessarily.

Figure 4. FreeMove triggers a robot stop when dynamic PSD is violated.

Using a dynamic PSD results in shorter average PSDs, which means less downtime when the robot is not working, and greater productivity of the workcell as a whole. A human operator can get much closer to the robot before it stops, so the robot operates for more time during each human entry event. If the timing is right, a human operator can even reach one of the pallet racks before FreeMove deems it unsafe and stops the robot. After the operator finishes the task, steps away, and reinstates the PSD, FreeMove signals the robot to restart.

For this workcell, we estimate that the average distance between the robot and human before the robot is triggered to stop is about 1.3 meters with FreeMove, compared to 3.9 meters with traditional sensing devices. This means that with FreeMove the robot can continue to operate for the time it takes a human operator to travel an additional 5.4 meters (round trip), which translates into a downtime savings of 4 seconds per event, relative to traditional sensing devices (Figure 5).

Figure 5. Human entry event process before and after implementing Veo FreeMove.

Because FreeMove automatically stops and restarts the robot, there is no need to design, engineer, and assess the risks of custom automation, which translates to reduced time and costs when setting up the workcell. Moreover, the automatic restart capability saves between 2-5 seconds previously lost with manual restarts.

Adding the downtime savings from dynamic PSD and automatic restart, FreeMove is able to reduce downtime by 6-10 seconds per event. Depending on the frequency of human entry, this can quickly translate into sizable downtime savings. In subsequent posts we will explore how FreeMove improves the economics of this machine tending application in more detail. Stay tuned!